BEI XIANG , Ph.D.

Senior Application Development Engineer

Momentive Technologies

Strongsville, OH 44149

Summary

Thermal management materials loaded with boron nitride (BN) match the challenge of offering thermal conductivity, electrical insulation, low coefficient of thermal expansion and low density. As electronic devices continue to shrink in size while simultaneously increasing power output, new materials are required to dissipate heat more efficiently. Electronic devices used in telecommunications, electric vehicles, and LED lighting are just a few examples requiring innovation in thermal conductivity and electrical insulation. Momentive Technologies produces several types of BN for varying needs in thermal management.

BN is one of the most attractive fillers for improving thermal conductivity while maintaining the electrical insulation of polymeric thermal management materials used in electronic devices. Agglomerate BN particles exhibit much better isotropic thermal performance than platelet BN powders. The impact of compounding conditions on the morphology of agglomerate BN, which is critical to the final composite thermal performance, is studied herein. It is demonstrated that the final thermal conductivity of polymer composites filled with the same percentage of agglomerate BN could have as much as 4x difference in thermal conductivity depending on compounding conditions.

Introduction

As more and higher power chips are incorporated into smaller size electronic devices used in electric vehicles, 5G telecommunication, LED lighting, etc., power density increases tremendously. In these electronic devices, heat generated within the diminished space must be dissipated more efficiently to help avoid heat buildup that could quickly throttle the device performance and possibly result in failure. The miniaturization of many mobile electronic devices makes active cooling more often than before not a feasible choice for thermal management design in current and future devices. The desire for an enhanced passive heat dissipation solution combined with the requirement for weight reduction of the whole package has forced thermal designers to look for innovative, high performance, lightweight thermally conductive materials to use in different components of the electronic devices, such as thermal interface materials (TIM), housing materials, heat sink fins, and heat spreaders [1].

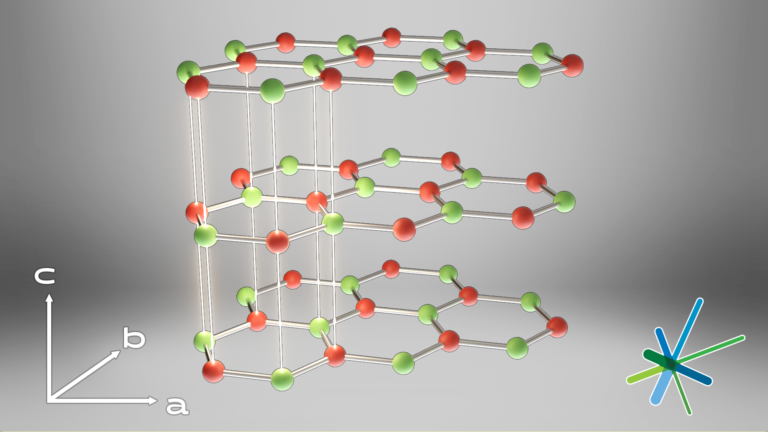

Thermoset polymers, such as silicone and epoxy, have been extensively used for preparing thermal interface materials for decades. Because of the thermally insulative nature of polymers (thermal conductivity ~0.2 W/mK), ceramic fillers such as Al2O3, ZnO, etc. have been used for improving the thermal conductivity of polymer composites. However, the thermal performance criteria of TIM are increasingly demanding. TIM makers are facing greater challenges in achieving the thermal management requirements of today’s high performance electronic devices. h-BN is a superior thermal filler with the highest in-plane thermal conductivity (>300 W/mK) and lowest dielectric constant when compared to typical ceramic fillers found in polymer composites. However, the anisotropy in h-BN’s thermal conductivity greatly limits the thermal performance of the TIM made of BN-polymer composite in the direction needed. To solve this issue, agglomerate BN, whose particles are the random agglomeration of fine platelets, has been developed. Because of the random orientation of the platelets in the agglomerates, the thermal performance in all directions is very close if not equal. Significant improvement of all-direction thermal conductivity (TC) has been achieved for polymer TIM filled with agglomerate BN [2]. However, the optimal thermal and rheological performance are often not obtained by (new) users because of the lack of understanding on the compounding conditions impact on BN morphology, which directly influence the thermal and rheology performance of BN filled polymer composites. Therefore, a study was conducted on the correlation of compounding conditions and BN morphology with final polymer composites’ thermal performance.

Studies and Results

Impact of BN morphology on BN-polymer composite’s thermal performance

Momentive Technologies h-BN powder can be categorized into two major morphologies – platelets and agglomerates. Among agglomerates, there are also agglomerates in irregular shape or close to spherical shape. Various sizes and shapes of platelet BN and agglomerated BN were compounded at specified levels (wt. or vol.%) in silicone resin with a crosslinker at 3500 rpm for 30 seconds in a SpeedMixer. The mixture was then cured in a compression mold to produce ~0.5-1.3mm thick pads for through-plane thermal conductivity measurement by Netzsch Laser Flash LFA447. A comparison of in-plane and through-plane TC of BN-silicone composites made with 40wt% platelet BN and spherical agglomerated BN is demonstrated in Figure 1 Spherical BN powder grades delivered higher & more isotropic thermal conductivity than platelet BN at the same loading level and compounding conditions.

Effect of compounding conditions on the through-plane thermal conductivity of BN-polymer composites

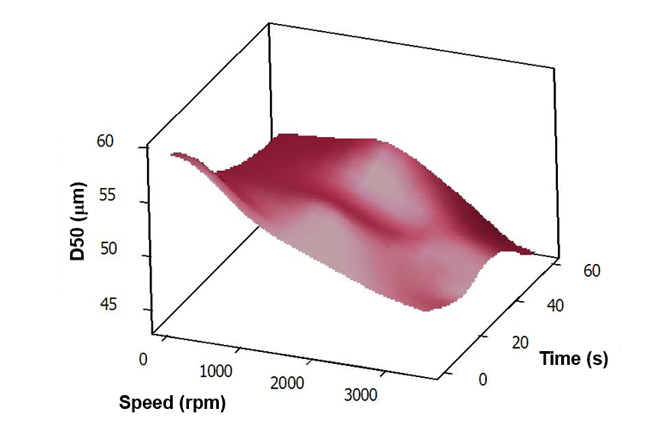

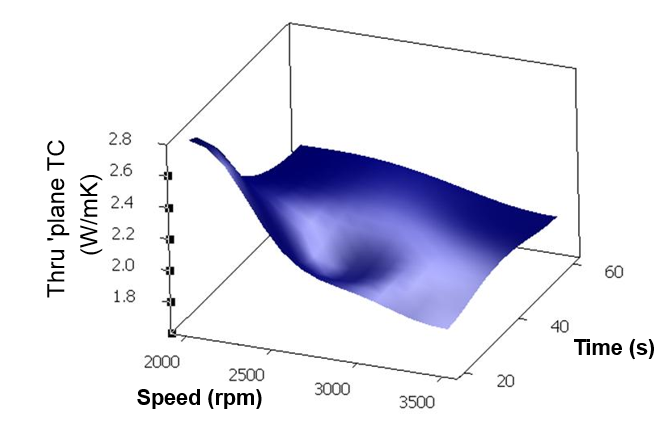

PTX60 is a special BN powder with particles close to spherical shape. These spherical shaped agglomerates provide the best isotropic thermal performance as shown in Figure 1. However, the agglomerate of the building platelets could be broken under high shear when aggressive compounding conditions are used in compounding process with polymers, leading to particle size reduction and the loss of spherical agglomeration. As shown in Figure 2, when compounding with silicone by SpeedMixer, different combinations of blending speed and time led to different levels of agglomerate breakdown. The morphology change resulted in a significant impact on final BN-silicone composite through-plane thermal conductivity. The final through-plane TC of the same formulation varies 4x between the lowest and highest values depending on the combination of blending RPM and blending duration. These results demonstrate the importance of choosing the right compounding conditions when processing agglomerated BN with polymers.

(a)

(a)

Test data and results. Actual results may vary.

Figure 1. (a) Platelet Vs Spherical agglomerate. (b) PTX60, PTX25, PT371, PT350 are agglomerate BN with different sizes and morphologies, while PT110 and PT120 are platelet BN.

(a)

(b)

Test data and results. Actual results may vary.

Figure 2. (a) Effect of mixing Speed & Time on BN agglomerate morphology. (b) Effect of mixing Speed & Time on through-plane thermal conductivity.

References

[1] Z. Carl, “Advances in composite materials for thermal management in electronic packaging’, JOM, June 1998, Volume 50, Issue 6, pp 47–51.

[2] L. James, J. Peter, “Thermally conductive interface materials and methods of using the same”, U.S. Patent 5, 213,868 A, issued May 25, 1993.